PCL805 Tube Headphone Amplifier

RKV mkII

- by Helmut Becker

I

was allowed to publish this report, which was published in the magazine ELRAD 1984,

issue 6, with the express kind permission of Mr. Helmut Becker ( www.audiovalve.de) on

the Jogis-Röhrenbude homepage. All rights of the author, Mr. Becker,

remain unaffected.

All photos and texts shown on this and the associated sub-pages (including

extracts), should they be passed on to third parties, require my express

consent.

Any commercial use is hereby prohibited.

Most stereo

equipment manufacturers pay little attention to the fact that headphones are

some of the best transducers.

Almost all amplifiers have a headphone output, but this usually represents a

very bad compromise in terms of its technical design.

Plain, bad and simple

Usually the headphones are simply connected in parallel to the loudspeaker

terminals, whereby the loudspeaker can be switched off if desired. Since

there are headphone systems with an impedance of 8 to 2000 ohms, a resistor of

around 300 ohms is placed in the headphone lead, which in 8-ohm systems causes

an overload due to excessively high voltage but, on the other hand, does not

cause a noticeable voltage drop when connecting high-impedance systems .

So far it works pretty well. Unfortunately, it is too often forgotten that

dynamic headphones, like loudspeakers, require damping due to the low internal

resistance of the amplifier output. The mentioned series resistance

prevents this consequently.

Another shortcoming of this solution lies in the fact that the supply voltage

of loudspeaker amplifiers is usually too low. Hi-fi headphones are almost

exclusively high-impedance (600-2000 ohms) and need a correspondingly high

voltage for control. The power amplifiers designed for low-impedance

loudspeaker loads cannot keep up here. The consequence is a separate

headphone amplifier.

Effort that is worth it ...

A loudspeaker amplifier with a very low internal resistance should supply a

very low-resistance load with relatively low voltages and high currents, a task

that is tailored to the transistor.

However, we want to supply a relatively high-resistance load with comparatively

high voltages at low currents, although with a low internal resistance. Of

course, this also works with transistors. But we remembered a component

that the older ones still have fond memories of.

The tube is coming ...

For the catalog of tasks described above, a tube assembly is ideal. High

supply voltage is a necessity for tubes, so they can also handle high signal

amplitudes. Since the load is high-impedance, you can do without the

output transformer that is unavoidable when using loudspeakers. This leads

to an ironless tube power amplifier of the highest quality, which is far

superior to most transistor amplifiers.

... the transistor stays.

However, we haven't completely banned semiconductors. Wherever tubes have

their weak points - they are subject to certain manufacturing tolerances and,

as components subject to high thermal loads, they show relatively severe aging

- semiconductor components take on the task of controlling and regulating

fluctuations in the operating point.

When connecting headphones to the output of a loudspeaker amplifier that has

been rated as excellent up to now, one often learns what else arrives apart

from music. It rustles, buzzes, crackles and hisses ... and the

loudspeaker does not notice any of this.

Naturally, headphones are much more sensitive transducers than

loudspeakers. Even the slightest noise and hum tensions are mercilessly

brought to the ear. The requirements for a headphone amplifier are

correspondingly high.

Can be heard

The circuit shown, which was developed by Helmut Becker and registered for a

patent (P 3200 517.2), also shows excellent behavior here. A comparison

with the P 3090 from Onkyo quickly revealed that there were no significant

differences to the much more expensive reference. Together with the

dynamic DT 880 Studio headphones from Beyer, the amplifier reproduced

everything that was in the grooves, cleanly and naturally. He brought

dynamic passages and solemn passages impeccably. Solo voices and orchestra

came with very little coloration.

In brief, the advantages of the circuit concept once again:

- excellent metrological

data (see below)

- tonally balanced,

sharply contoured, powerful sound

- high dynamics, so

CD-compatible

- high damping factor,

lowest internal resistance

- ironless adaptation to

impedances between 30 and 3000 ohms

- Can be expanded with a

preamplifier and thus upgraded to a linear integrated amplifier

The circuit

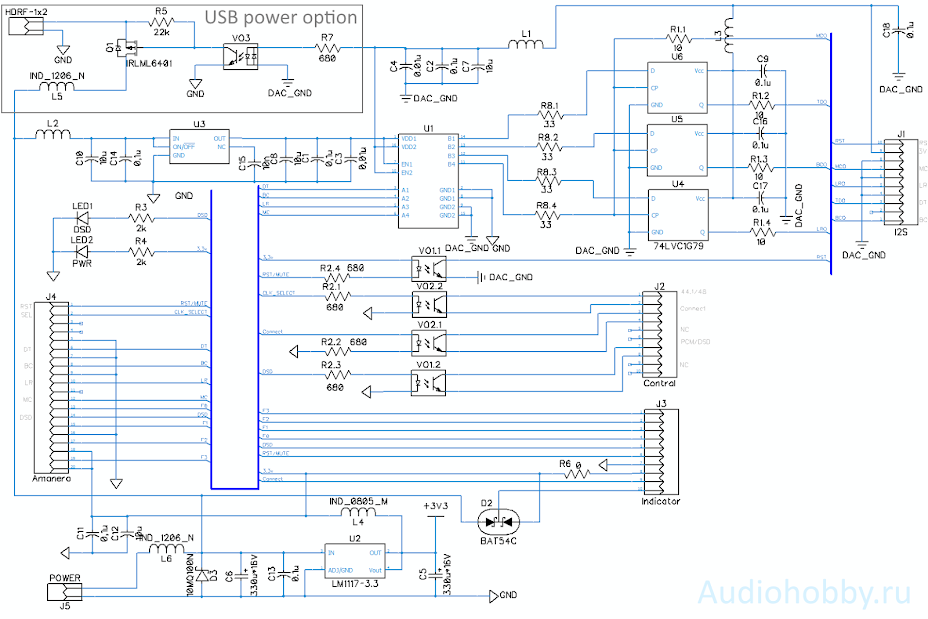

As can be seen from the circuit diagram (Fig. 1), the two output tubes are

connected in series in terms of DC voltage, so that the available supply

voltage is distributed over both tubes.

Fig.1

In order to avoid an unnecessarily high operating voltage, tubes would have to

be used which still allow strong currents at an anode voltage of around 150

V. Since the range of LF tubes is consistently matched to high anode

voltages, the choice fell on a tube type that was standard equipment on

television sets around ten years ago.

The triode-pentode PCL 805 meets the above requirements, but has serious

disadvantages in other respects, which must be taken into account and

eliminated in the rest of the circuit concept. For example, the relatively

strong heating hum of this type of tube is effectively suppressed by a control

circuit and the strongly curved control grid characteristic is compensated.

The block diagram shown above illustrates the circuit principle, which is based

on three functional groups.

- Reference voltage

source as a reference point for all controlled variables

- Operational amplifier

as a control element

- Tube power amplifier

The tube output stage

The tubes 2 and 3 are connected in series in terms of DC voltage and therefore

carry the same current. If it is ensured that an equally large voltage

drop occurs on both tubes, the maximum possible modulation is achieved, tube 1b

works in anode-base circuit, while tube 2b is used in cathode-base circuit. The

negative grid bias of tube 2b defines the operating point of the output

stage. It is advisable to choose the operating point for AB operation.

The tubes 1a, 2a serve as driver stages and at the same time ensure the

antiphase control of both output tubes.

If the grid voltage at tube 2b

increases, the grid voltage at tube 1b must decrease - and vice versa. In

the process, the voltage potential at the connection point A between the tubes

1b and 2b is shifted. The entire arrangement works like an electronic

potentiometer, which is placed between ground and supply voltage and whose tap

leads to the output electrolytic capacitor C2.

The operational amplifier

The tasks of the operational amplifier are:

- Check the operating

points of the DC coupled amplifier

- Control of the AF

signal to be processed

In order to monitor the operating points

of all amplifier stages from one point, a galvanic coupling is

necessary. As can be seen from Figure 1, this is the case for the tube

systems Rö 1a, 2a, 1b. The operating point of Rö 2b is determined solely

by the negative grid bias. A certain internal resistance arises for Rö

2b. The voltage potential that results at point A is divided down with R1

and R2 and compared with the reference voltage URef by the OpAmp.

The output

voltage of the OpAmp will now shift the operating points of the tubes Rö 1a and

Rö 1b until the voltages at the inverting and non-inverting input of the OpAmp

match. The reference voltage URef at the inverting input of the OpAmp thus

determines the voltage potential at point A.

If URef is selected so that half the supply voltage U a is at

point A , the two output tubes have the same internal resistance, the same

power loss is implemented in both, and the controllability reaches its maximum.

Figure 1 also shows that the reference voltage is superimposed on the LF input

voltage. When modulated, the operating points will shift in the rhythm of

the input voltage in the sense that a true copy of the input signal is created

at the output of the amplifier - but amplified by the resistance ratio of R1

and R2.

The rather complex control circuit gives the circuit some remarkable

properties. A problem with tube circuits is the heater hum. The

alternating current flowing through the filament of the tube creates a magnetic

field which of course also penetrates the cathode and can lead to a 50 Hz

modulation of the anode current.

Since such a hum disturbance occurs within the control loop in the circuit

concept described, it is largely corrected if only the reference voltage is

clean and hum-free. However, this requirement can be met very easily by

good sieving and smoothing with a fixed voltage regulator.

Signal-to-noise ratios of 130 dB (A) can be achieved in this way.

Another advantage of the circuit concept is the complete compensation of the

characteristic curve curvature of the tubes used. Manufacturing-related

tolerances and age-related shifts are automatically compensated. In

addition, the regulation, which corresponds to a strong negative feedback in

terms of alternating voltage, ensures an extremely low internal resistance of

the output.

Power supply unit

Although the amplifier with its mixed equipment requires a large number of

different supply voltages, the mains transformer manages with two secondary

voltage windings.

To generate the anode voltage, a winding with 250 V and

100 mA load capacity is sufficient to supply a stereo output stage.

The second winding generates the heating voltage for the tubes:

The PCL 805

requires 18 V at 300 mA heating current.

Since two tubes are connected in

series, a transformer voltage of 36 V with 0.7 A load capacity should be

selected.

The positive and negative supply voltage of the OpAmp as well as the negative

grid bias voltage for Rö 2b and the positive reference voltage URef are also

derived from this winding.

(Corrected Schematic, see text.)

*****C23 is 220nF/100V is missing in the original schematic!

****Adjust P1 to make a ~3.5Vdc voltage bias on the node of C13 and R13.

Construction

Unfortunately, a double-sided circuit board could not be avoided when

developing the circuit. For this reason, self-production is reserved for

the experienced etcher.

When equipping, it is advisable to start with the power supply unit. All

components that are used for the power supply must be soldered in.

These

include the rectifier Gl1, the diodes and Zener diodes D1-4 and D11, the

capacitors C1-14, the resistors R1-5, the trimming potentiometer P1, the fixed

voltage regulator IC1 and the two fuses Si 1, 2.

Before you start the Connect the transformer and check the voltages, a word

about dealing with high voltages: The anode voltage of the device is over 300

V!

That is a value that may be enough to send you to the eternal hunting

grounds.

Only work on the device when it is switched on if it cannot be avoided and then

with extreme caution. Above all, remember that after switching off the

device, the voltages on the high-voltage electrolytic capacitors C14, 24, 24 ',

25, 25', 26, 26 'are retained for a long time.

So before you grasp heartily with both hands, even when the device is switched

off, you should discharge the capacitors mentioned.

This is done via a 1

k, 4 W resistor, by no means through a short circuit, because an electrolytic

capacitor does not like it when it has to supply currents of over 10 A for a

short time.

Now switch on the device and check the voltages relative to ground:

at C14 approx. +315 V

at C4 approx. -18 V

at C8 approx. +22 V

at C10 approx. +12 V

at C12 approx. + 6V

The voltage at C13 is initially set to

about 3.5 V with the spindle trim potentiometer P1.

If the voltage values are correct, after switching off the device and after

discharging the electrolytic capacitor, the next step is to solder in the tube

socket and insert the tubes in order to then convince yourself of the function

of the heating filaments.

After switching on the device, the glowing

heating wire should be visible at the upper end of the inside of the tube after

a few seconds.

After switching off and unloading again, the rest of the equipment begins.

Once all components have been soldered in, the amplifier can be put into

operation and adjusted. To do this, the voltage at C26 or C26 'is

measured.

It should initially be between 100 and 250 volts and can now be

set to around 160 volts with P1.

If you now short-circuit the LF input and check the output signal with an

oscilloscope, nothing should be seen except for a very small noise

signal. The same test is carried out on the second channel.

To set the symmetry, a 1 kHz sinusoidal signal is applied to the amplifier

input.

The output is loaded with a 390 Ohm, 4 W resistor and the output

signal is monitored with the oscilloscope.

Now increase the input voltage

until the limitation of the output voltage is visible on the screen. By

slightly readjusting P1, the operating point is shifted until the limit is the

same for a positive and a negative half-wave.

No distortion of the

sinusoid should be visible until shortly before the limitation starts.

If you do not have an oscilloscope available, you can be satisfied with

bringing the voltage at C26, C26 'to half the anode voltage.

Technical data (measured on the finished device) :

Output line: 3.4 W at 100 Ohm

RMS at 1 kHz 1% Kges. : 6.6 W at 600 ohms

THD : 0.007% at 100 ohms

1 kHz / 100 mW: 0.004% at 600 ohms

Intermodulation: 0.008 at 100 ohms

600/6000 Hz, 4: 1: 0.005 at 600 ohms

Power bandwidth : 2 Hz - 120 kHz at 100 ohms

-3 dB: 1 Hz - 140 kHz at 600 ohms

Damping factor:> 10 4

Input sensitivity:

0.2 V for 1 watt at 100 ohms

0.5 V for 1 watt at 600 ohms

Input impedance: 100 kOhms (without Volume poti)

Signal-to-noise ratio:

113 dB (A), 50 mW at 600 ohms

138 dB (A), 2 W at 600 ohms

Output voltage: 80 V (RMS)

Rise time (40 V at 600 Ohm): 80 V / uS

Power output: 2 - 3 dyn. Handset (imp. Approx. 400 ohms)

Mains connection value: 220 V / 50 Hz, 40 VA

The circuit board - layouts and assembly

(Layout of the wiring side)

(Click on the

respective layout with the mouse button, it will then be displayed in full

resolution.) (Layout of the component side)

The parts list for this headphone amplifier:

This amp is still offered today (of course with some improvements in the

meantime) at Audiovalve under the name RKV Mark II:

About Tubes:

ECL85/6GV8-XCL85/9GV8-LCL85/10GV8-PCL85/18GV8

is a very good tube for audio amplifiers, very linear, with lower internal resistance and

with lower supply voltages uses an output transformer of lower primary impedance

(read: cheaper!)

than the tube ECL86 / 6GW8-PCL86 / 14GW8, which is much cheaper and lighter to procure.

The improved ECL805 / PCL805 variant, which has an increased maximum plate dissipation (especially from TELEFUNKEN) of Pa = 11W, is even better, but it is also increasingly difficult to find.

Due to reliability Problems the PCL85 (Pa= 7W) became the successor PCL805 (Pa= 8W) where nothing else had been changed except the pentode power rating.

For the same reason the pentode part had been put into a single envelope, which was named PL805 then (with "E"-Heater also produced as EL805).

It is very easy to mistake the PCL805

for the PCL86 from the outside - especially if the lettering has become

illegible. - So take care!

The following photos show a PCL805 (left, Philips production) and a PCL86

(right), each side by side. - Since both are Valvo-labeled, the slight

differences that can be seen (anode sheet, etc.) could be due to internal

reasons.

It is therefore quite possible that an ECL805 and an ECL86 from a different

manufacturer have slightly different differences, or could even be completely

similar!